Polypropylene wafer check valve

Save energy with our revolutionary non-return valve design.

Product advantage

The standard polypropylene wafer non-return valve

- High quality machining and assembly.

- Perfect sealing of the shaft and disc.

- Excellent chemical and mechanical resistance.

Polypropylene wafer check valve with optimized fluid passage: the PP eco-valve

- Optimized pressure drop with up to 80% gain.

- Expanded open area to increase the flow through the valve.

- Manufactured in pharmaceutical and food grades. Fully recyclable.

- Available in standard sizes from DN 50 to 250 mm.

The polypropylene wafer check valve with optimized fluid passage: the PP eco-valve

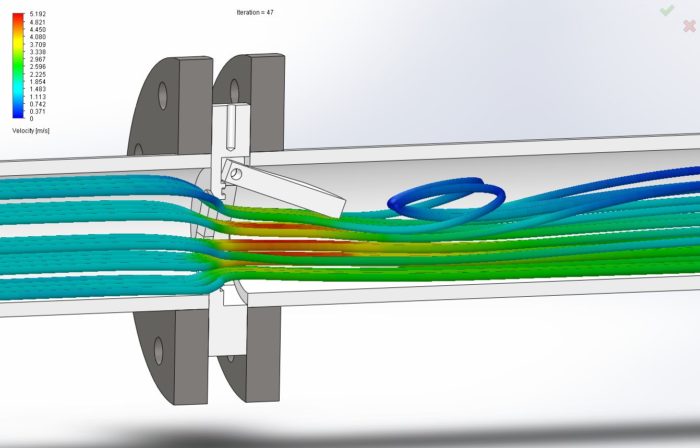

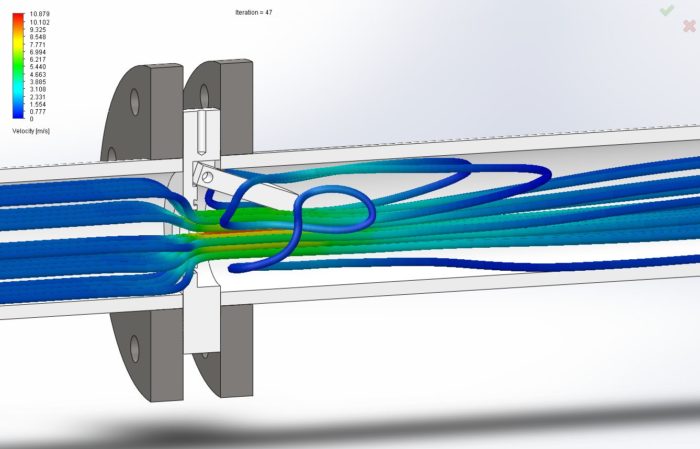

The K2 eco-valve® is the ecological and economical answer to a key problem in fluid dynamics: pressure loss. But what do we mean by pressure loss? Well, to simplify, any obstacle encountered across the passage of the fluid modifies the effort required to make it flow. It is simple and yet no one has questioned the possibility of reducing this pressure drop. But, by working with high-performance CAD/CAM and 21st-century simulation tools, we have succeeded in considerably increasing flow performance, particularly through the reduction of pressure loss.

The optimized polypropylene wafer check valve reduces pressure losses by up to 80% and increases the flow area by up to 70%, depending on the DN. This opens up real opportunities for energy savings, so we have called it the ecoclapet®. Are you interested in our research? Learn more here: our research report.

The standard polypropylene wafer swing non-return valve

Keeping excellence at the core of our values and for the purpose of our research, before creating the eco-valve® in polypropylene, we first developed a line of standard products that have been continuously redesigned and improved.

This standard PP valve benefits from all our technical production and design expertise.

We first analyzed all the pipe diameters available on the market. Then, we redesigned the sealing system of the shaft and the disc, and manufactured custom installation elements. In fact, at K2, we created a proprietary design for the stainless steel pin to ensure correct positioning and convenience during the installation of the valve. Finally, we have reworked the thicknesses and mechanical strength to avoid inertia during closures.

This type of valve can be used as a replacement in existing production lines when it is difficult to mud flapmodify on-site installations and layouts.

What is a polypropylene swing non-return valve?

Wikipedia defines a valve as a: « device that regulates, directs or controls the flow of a fluid ».

The simplest of these devices is called a check or non-return valve, as it prevents or “checks” the flow in one direction. But at K2 Valves we didn’t stop there. We will explain why and how we designed a revolutionary polypropylene swing non-return valve.

We started by drawing a simple form that we designed and analyzed. This extensive analysis paved the way for a first optimization on the standard polypropylene wafer non-return valve.

Then, based on this first collection of technical data, we developed a new form of PP wafer swing check valve: the K2 eco-valve®, which allows you to save up to 80% on pressure losses.

Technical data on the PP swing check valve

Some technical data anyway!

The polypropylene swing check valve is available in sizes ranging from DN50 to DN250, or larger upon request. We have implemented high-performance seals that have been carefully positioned and adapted to achieve perfect sealing.

Our in-house design and engineering office allows us to guarantee perfect manufacturing and to propose solutions to the problems you may encounter.

In this page, you will find details about the polypropylene non-return valve that we have developed in 2 other plastic materials: PVDF and PVC.

Technical data sheet

- Installation between ISO/DIN flanges; ANSI; BS

- Centered right in the middle of the valve body using flanges

- Horizontal or vertical mounting inupward flow conditions

- Stainless steel coding for easy installation, handling, and operation

- Sealing by Viton O-rings

- Compact design

- No specific maintenance required

- Available in diameters from DN50 to DN250, for pressures from PN10 to PN25.

- Our design office

The polypropylene of the check valve

Why polypropylene for the check valve?

Polypropylene is widely used in the field of industrial piping and valves. It is a material with outstanding properties; it has the best ratio in terms of chemical compatibility/price.

It can handle temperatures up to 100 degrees and the entire pH range from pH 2 to pH 12. In addition to its great mechanical resistance, and the fact that it can be approved for food and pharmaceutical applications. Therefore, you can easily understand why we have chosen this versatile and economical material for our non-return valve.

Of course, not everything is perfect in the world of polypropylene check valves. It still has a lower mechanical strength compared to stainless steel, but it can be advantageously replaced by complementary materials such as PVDF, Teflon, or PVC.

Depending on the application, we have developed a complete range in a variety of materials to best meet your mechanical, chemical and economic requirements.

[gravityform id=”4″ title=”true” description=”true”]